- 03/14/2019

- 2 Min Read

- By: Gareth Foley

How To Repair Damaged Axle Shaft Threads On Your BMW (E36, E46, E90 & More)

Have you ever tried to rush something that you know you shouldn't and instantly regretted it? I think we've all been there before; trying to save a few minutes now costs you hours (and usually money) down the line. I admit I did just that, and it nearly destroyed a very expensive axle. Use this guide as a lesson, hopefully preventing this from ever happening—and if it does, this is how to repair the damaged threads on your axle shaft.

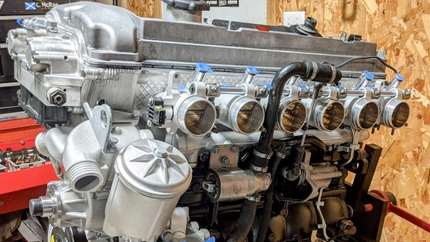

A few weeks ago I made a remarkably rookie mistake while I was trying to quickly disassemble an entire BMW E36 M3 rear end for easy transportation. My goal was to remove the axle shafts from the trailing arms before throwing those and all of the other parts in my truck, but naturally, that wasn't in the cards. Some BMW (and other vehicle makes) axle shafts and wheel hubs interface together almost as if they're press fit. Couple that with two decades of being affixed together and it's not surprising that they didn't come apart easily.

I tried to remove the first of the axle shafts with the classic "pound the snot out of it with a hammer technique" knowing in the back of my head that nothing good could have come from it. While giving the axle shaft a few firm love taps with a sledgehammer, I noticed I hadn't entirely threaded the axle nut back on. As with the way things go, this messed up the threads on the axle shaft and made removal of the (now destroyed) axle nut a real joy. After some choice words to myself and a re-evaluation of my life, I summoned the courage to take a look at my handy work.

If I remember correctly, and I'm pretty confident that I do, I yelled "F*ck!" and followed it up with a nice solid face-palm. This now famous Jean Luc Picard meme illustrates my disgust nicely:

As noted I was pretty disgusted with myself. The feeling of knowing that I may have destroyed an expensive axle due to nothing more than my own pure carelessness with a blunt, ill-suited instrument, still bothers me. I've done worse before while working on cars, but this was nothing but rushing to get something accomplished that I could easily have dealt with later when I wasn't rushed. Lesson learned (again), and we'll leave it at that. Let's get into the axle shaft thread repair.

Step 1: Axle Shaft Removal (If Needed)

I ended up using a 12-ton hydraulic gear puller to push the axle out. This worked incredibly well. And shocker, no additional dummy-damage was done to the axle. Other tools will do this as well, like these non-hydraulic gear pullers.

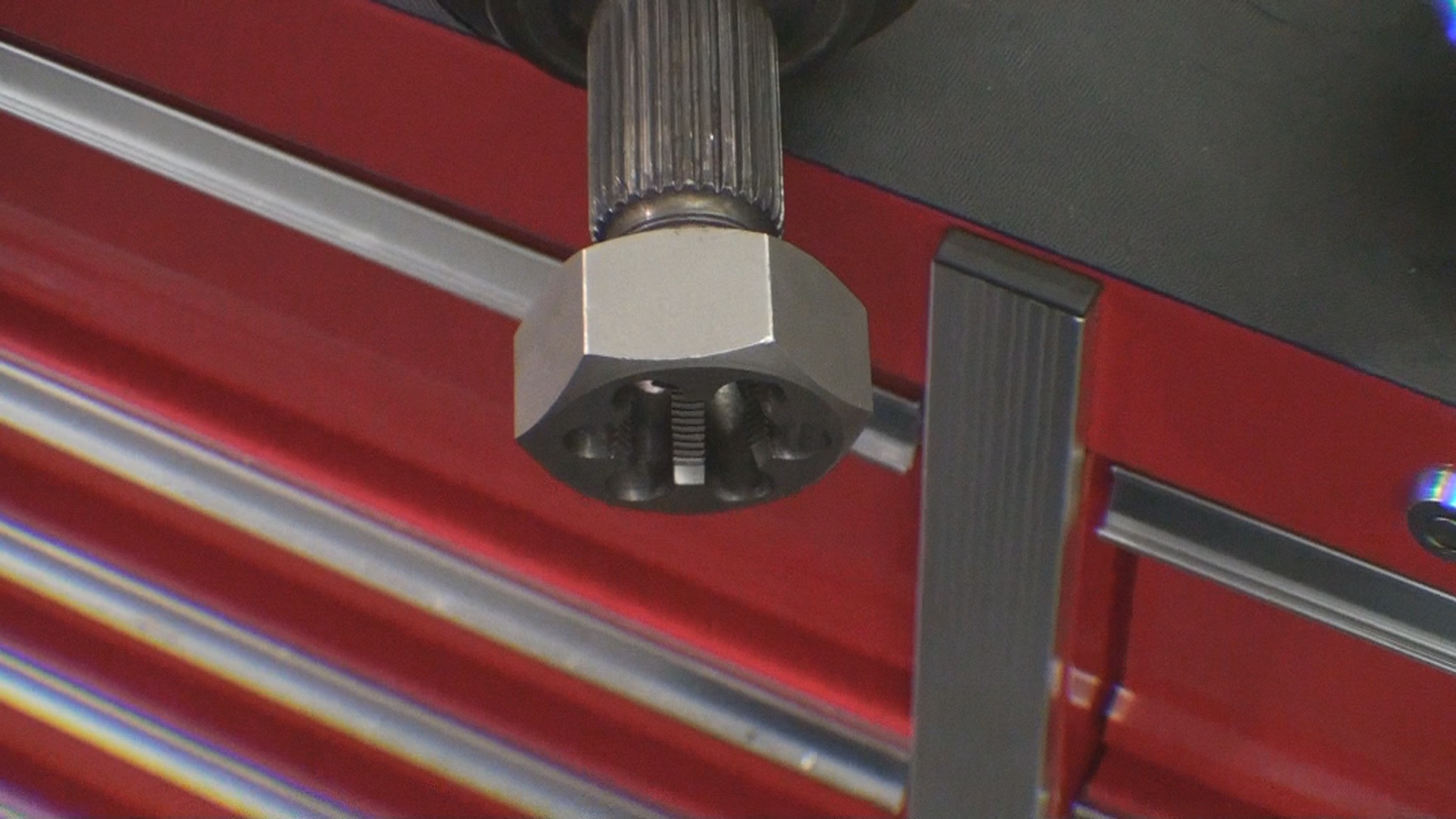

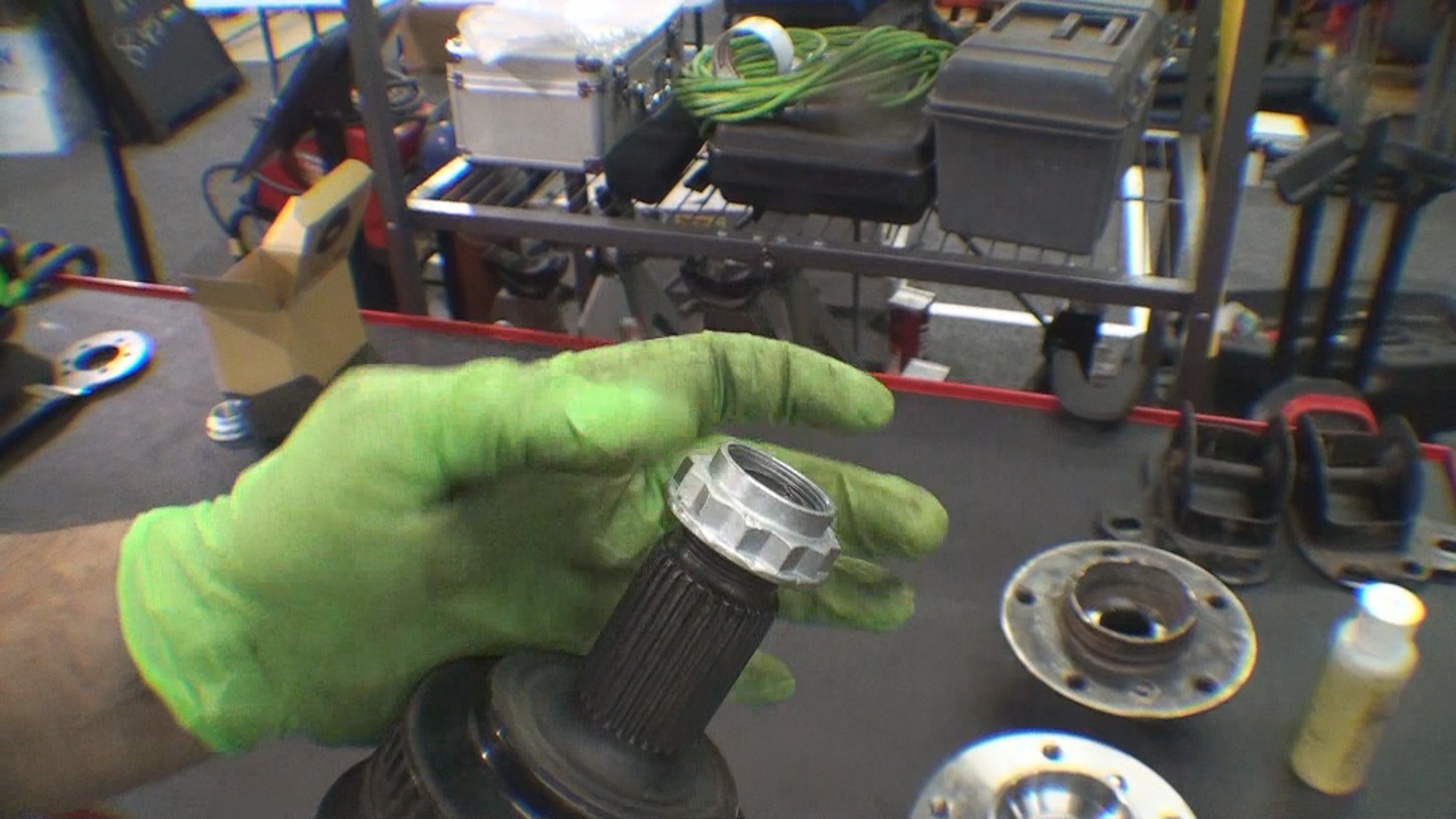

Step 2: Determine Axle Shaft Thread Size

The two most common axle shaft sizes for BMW are M24x1.5mm and M27x1.5mm. You need to know this to order the correct size re-threading die. In my case, E36 M3 axles use an M27x1.5mm axle nut. Around forty dollars, a few days of reflection time later, and I had my solution. Dies this large don't really have a special drive tool. In fact, the manufacturer of the die above mentions that directly on the product page. I used my 400mm Knipex Cobra Pliers (which are awesome) to drive the die.

Step 3: Secure The Axle Shaft

It helps to have the axle shaft secured in a vise while you do this. In my situation, I was able to get by without it, as only the first few threads were damaged. However, the more stable something is for a job like this, the easier it is to get the job done correctly.

Step 4: Start The Die By Hand

The die should line up nice and square. If it's crooked, try again until it bites on the threads and sits perfectly square. My die lined right up on my first try. Also, make sure you use some cutting oil or even regular some new or used LIQUI MOLY you have sitting around.

Step 5: Thread The Die On And Back Off

I worked my die a few turns forward and then would come back one full turn to make sure to clear the die from any chips or cut material. There should be very little during this job.

Step 6: Clean The Threads And Test Fit A New Axle Nut

Clean the freshly reshaped threads with some brake parts cleaner and try threading on a new axle nut. The axle nut should thread on smoothly and if it doesn't, run the die another time to clean up the threads further. In my case, one go was all I needed to fix the threads completely.

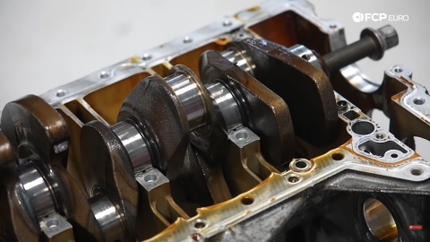

You should be aware that there are cases in which threads are beyond the point of repair. If a majority of the threads are damaged or have been stripped away, don't bother attempting this fix; there just won't be enough usable material left to make this work. After the repair, visually inspect the threads for uniformity. If the damage happened in the area in which the axle nut torques down, it's critical to make sure the repaired threads are uniform and consistent.

This repair can definitely save you, but you should use some sense and know when an axle cannot be salvaged. If that's the case, we recommend purchase and replacement with a new axle. If you'd like to get more of these DIYs make sure to check back often as well as subscribe to our YouTube. For updates on this project, you can start by following along here.