As we approach the summer months, air conditioner use becomes a daily ritual; discovering that the A/C functions intermittently could be devastating. When an air conditioner begins to fail, the most common thought is that the A/C needs a refrigerant recharge. However, low refrigerant is not the cause for an A/C which intermittently blows cold air. If you find that your A/C functions properly for only the first few minutes of use, the problem is most likely associated with the A/C compressor clutch.

Being a wearable item, the compressor clutch is slowly being worn away during A/C operation. Even when you have the air conditioner cranked to max, the clutch is still cycling between being engaged and disengaged. This saves the compressor from constantly running and burning itself out. However, if the clutch has worn down a significant amount, it will have a hard time reengaging once the friction contact surface becomes hot. When the A/C first begins intermittent failure, it may function properly for as long as 30 minutes before cutting off. But as the clutch wears further down, this time span decreases. Depending on how long this problem has existed, the clutch may only remain engaged for the first few seconds before it slips and disengages the air conditioner.

A quick way to confirm compressor clutch failure is to manually turn the A/C on and off. Once the A/C clutch obviously disengages itself and begins blowing warm air, turn off the A/C with the button on the center console. Give the clutch a few minutes to cool down before turning the A/C back on. If the clutch has cooled down enough, it should then reengage without any issues.

Do not fret, because an intermittent A/C does not require purchasing an expensive compressor. On the contrary, it can easily be fixed in as little as 30 minutes with nothing more than basic tools. There is no need to remove the A/C accessory belt and no reason to drain the system of refrigerant. The solution is simply a matter of removing and/or replacing tiny washer shims which space the clutch away from the compressor pulley.

Tools Required To Fix Volvo A/C:

- Floor jack

- Jack stands

- Socket Set

- Ratchet Set

- T25 Torx driver

- Rubber mallet

- A/C clutch puller tool

- Three M5 screws, 40mm in length, with washers

- One M6 bolt, 50mm in length, with washer(s) and a nut

- Additional thin washer shims may also be necessary

Steps To Fix Intermittent Volvo A/C:

Step 1:

Jack up the front right wheel and securely rest the vehicle on jack stands, then remove the wheel.

Step 2:

Using the T25 Torx driver, remove the screws which hold the wheel well liner in place and remove the liner from the vehicle.

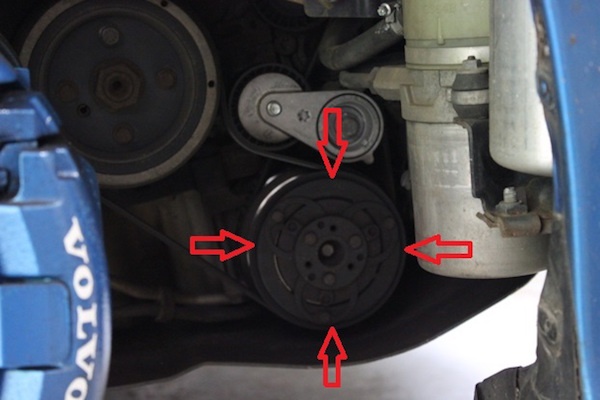

Step 3

Measure the current gap between the clutch and the pulley. Factory gap clearance should be about 0.3mm all the way around. If the gap is any larger, then it is time to replace or remove the spacer shims.

Step 4

Align your puller tool over the compressor clutch, insert the M5 screws a few threads onto the clutch, then use the puller tool to prevent the clutch from spinning freely as you loosen and remove the center 10mm bolt.

Step 5

Remove the M5 screws and puller tool, then assemble your M6 bolt with the nut and washers near the top.

Thread this bolt into the center of the compressor clutch and reposition the puller tool over this bolt, holding it in place with the three M5 screws. The center M6 bolt is to push against the puller tool as you tighten down the three M5 screws in sequence. This will slowly pull the clutch away from the compressor as it pushes against the threaded M6 bolt.

Step 6

Once the clutch is free, be extremely careful not to lose any of the tiny washer shims located in the center of the clutch.

Step 7

In most cases, there are two or three washer shims of various thickness in this center hole. Remove the necessary shims to get your clutch gap back to factory spec. It is vital that a 0.3mm gap remains. If the clutch does not have enough space to fully disengage, it will quickly burn out the compressor. You may need to provide different sized washer shims to get your clutch gap back into the specified range. If the clutch is significantly worn, such that removing all the shims will not provide sufficient gap, then it may be time to replace the entire clutch assembly.

Step 8

With the replacement shims in place, hammer the clutch back onto the pulley and repeat step 4 to re-tighten the clutch back onto the compressor.

Before replacing the wheel well liner and wheel, you may want to start the car with the AC on. Watch the clutch to confirm it engages, then turn the AC off to confirm it can successfully disengages. Do NOT turn the car on while the clutch is off the pulley or when any tools are attached to the clutch. This pulley spins at a rapid rate, so please keep tools and hands away while it is operating.

You should now be able to enjoy consistently cold air conditioning for many years to come. If you have any questions or comments, leave them in the comments section below.