- 12/21/2021

- 4 Min Read

- By: Gareth Foley

How To Replace BMW N54 Index 12 Fuel Injectors (E90, E82, Z4, X6, 740i, 535xi, 535i, 335i, 135i)

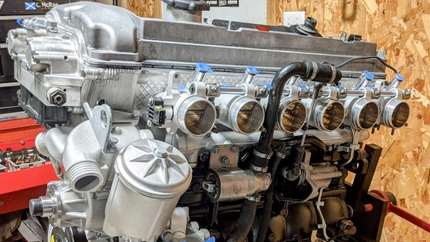

The N54 engine is a very popular platform with enthusiasts due to the potential power that can be unlocked. The stock fuel system was designed by BMW to be overkill, and unlike other direct injection cars, you can still drive comfortably with a high-pressure fuel pump failure. While this is impressive, the N54 fuel system as a whole can be a troublesome area on aging cars. One of the most common failures of the N54 happens to be the fuel injectors.

N54 fuel injectors are piezo-electric injectors; these have more in common with diesel injection than regular gas injectors. The reason for this is the piezo-electric injector uses a quartz crystal stack to control fuel flow versus a solenoid like most conventional injectors. This method allows for a higher volume of fuel to be moved. The main failure on earlier injectors is clogging and foreign debris restricting flow. On early N54 injectors, there's a filter that's known to melt at high temperatures. Once the filter fails the injector can no longer function properly.

BMW redesigned these injectors numerous times to address these failures. While some vehicles are still warrantied to this date, many of these cars have received replacement injectors numerous times over the course of their service life. What's important to know is that the updated injectors can't be mixed with the original style injectors. Any injector marked ten or lower in the same cylinder bank will require all the injectors in the bank to be replaced.

As of 3/26/2018, BMW has made it impossible to order #937 injectors unless the order was part of a warranty claim under a recall. We can no longer source or sell #937 injectors and will now be selling #079 injectors moving forward. However, the information listed below in regards to the #079 and #937 injectors is still relevant while both numbers are still listed in BMW's parts system. At the present time, the #079 injector has the material update that was once exclusive to the #937 injector.

Tools needed to replace BMW Index 12 fuel injectors:

- 14mm flare wrench

- Injector puller tool set

- E-Torx socket set

- Ratchet set

- Shop towels

- Pick set

- Magnetic pick-up tool

- Screwdriver set

- ISTA OBDII scanner

- OBDII to USB K+DCAN compatible cable

Parts needed to replace BMW Index 12 fuel injectors:

Steps to replace your BMW Index 12 fuel injectors:

Step 1: Remove Cowl, Rubber Gasket, & Engine Cover

This will vary based on the car you're working on, but the first step is to remove the cowl cover/air filter housing. This will give you access to the rearmost injector feed line and injectors. In most cases, this cowl will be in the way. On most BMW's the cowl cover is held in with clips and expanding rivets. I recommend having tools on hand such as a flat-head screwdriver and expanding rivet pliers.

Step 2: Disconnect and Remove Coil and Wiring Harness

With the cowl cover out of the way, it's time to start removing other components to get to the injectors. First, remove the ignition coil by pulling the lock tab up and the connector out. Then, pull the coil off the plug. I recommend removing all six at the same time. Also, go ahead and disconnect the electrical connector on the fuel injector.

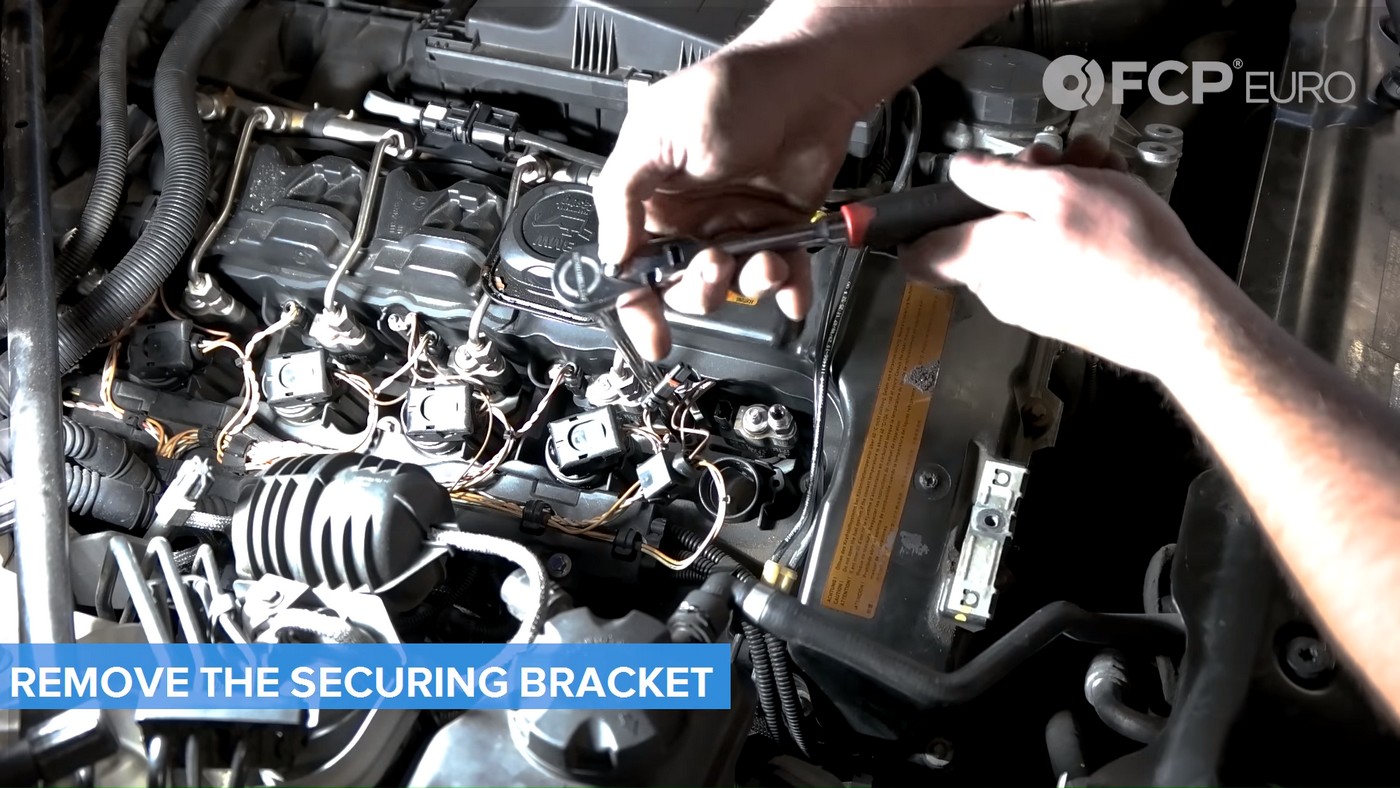

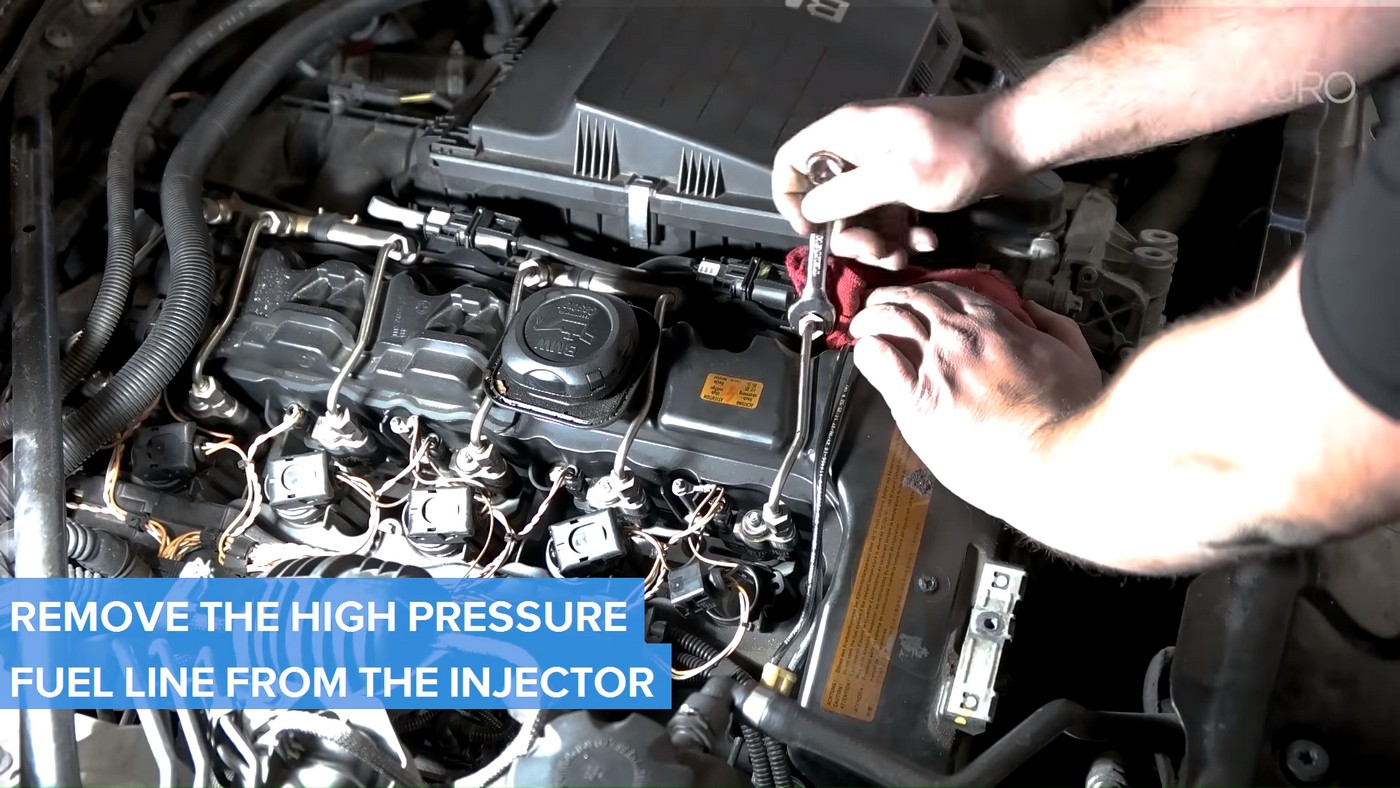

Step 3: Remove the Securing Bracket & High-Pressure Fuel Line

This next step you will need to break down into a process of thirds. Each injector is held down with a retaining bracket. The retaining bracket applies a downward force on the injector and keeps it seated in the cylinder head. One retainer bracket is used per two injectors. The retainer bracket is held in with an E10 socket. Once the bolt is loose, use a magnetic pickup tool to easily grab the bolt and retainer bracket.

Now it's time to release the feed line from the high-pressure fuel rail and the injector inlet. Use a 14mm open ended wrench, crowsfoot, or line wrench to release the nut. Use care as there's still pressure in the system. It helps to use a rag to block off fuel spray at the fuel rail. Once the nuts are removed, completely remove the line and set it off to the side. I recommend capping off the opening on the fuel rail to prevent foreign material from getting into the fuel system.

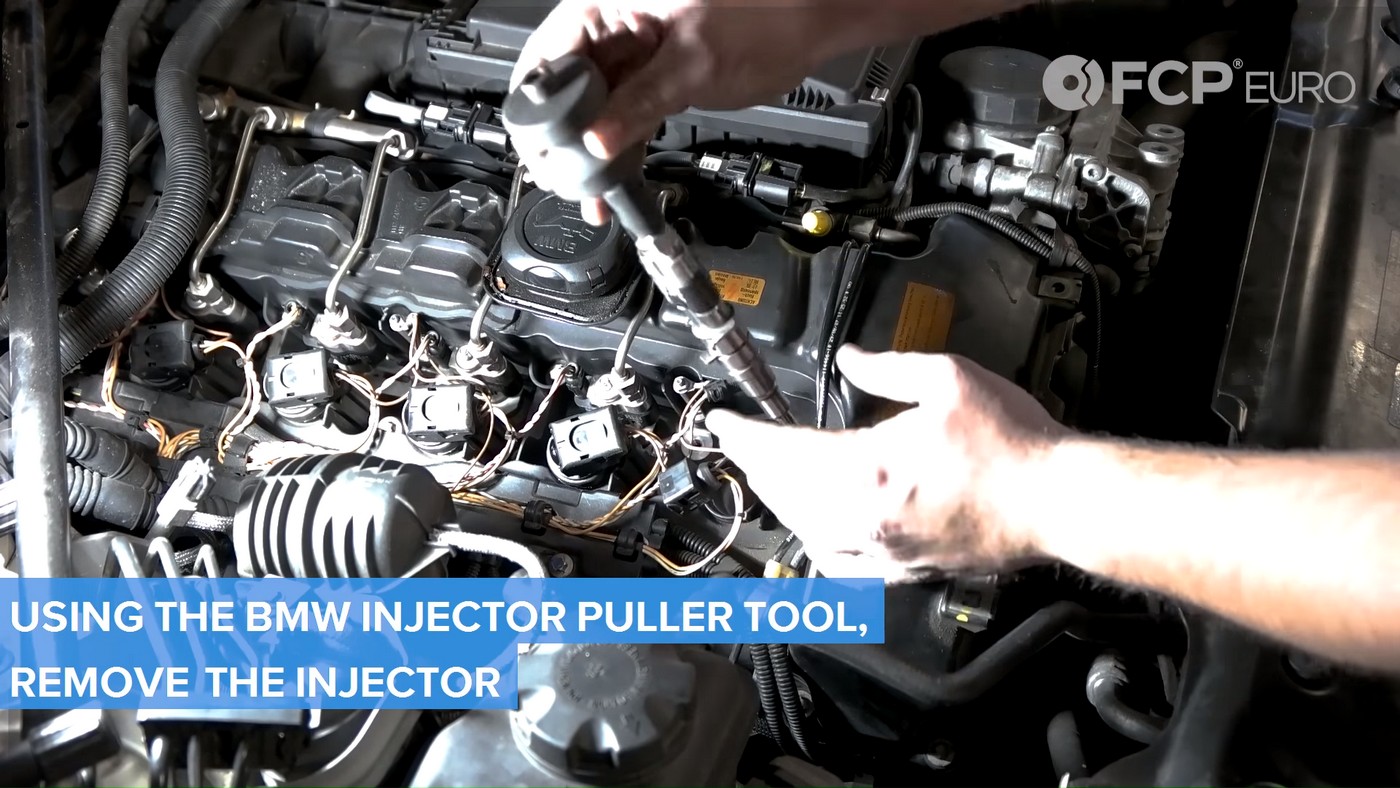

Step 4: Remove the Injectors

Before removing the injector, take an air-gun nozzle and clean any loose debris from inside the cylinder head where the fuel injector is seated. This will help prevent any sand or debris from falling into the engine when you remove the fuel injector. you will now be ready to remove the injector. I recommend the use of a small slide hammer to get this job done; the Viton seal can make removal of the injector tough to do by hand. A few taps of the slide hammer easily removes the injector. Once the injector pops out, prepare the new injector for installation.

Be aware of injectors that are already loose. The only reason they would be loose is if they had previously been installed incorrectly. Based on our own research, it seems that many injectors under warranty were installed without the proper decoupling element. Failure to install the decoupling element has been known to cause ovaling out of the injector hole in the cylinder head. If the injector is loose already and the decoupling element is missing, you may have a problem. Inspect the cylinder head and the shape of the injector hole.

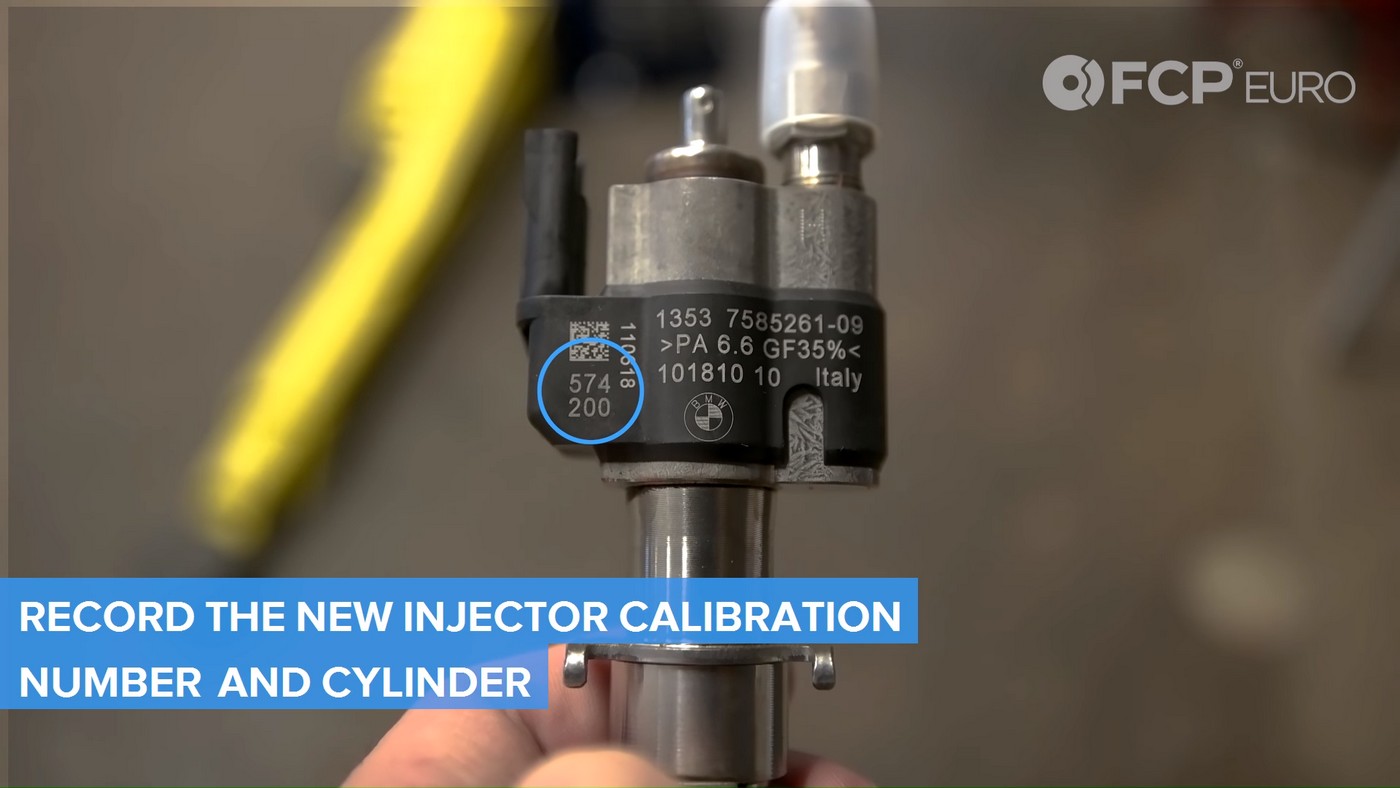

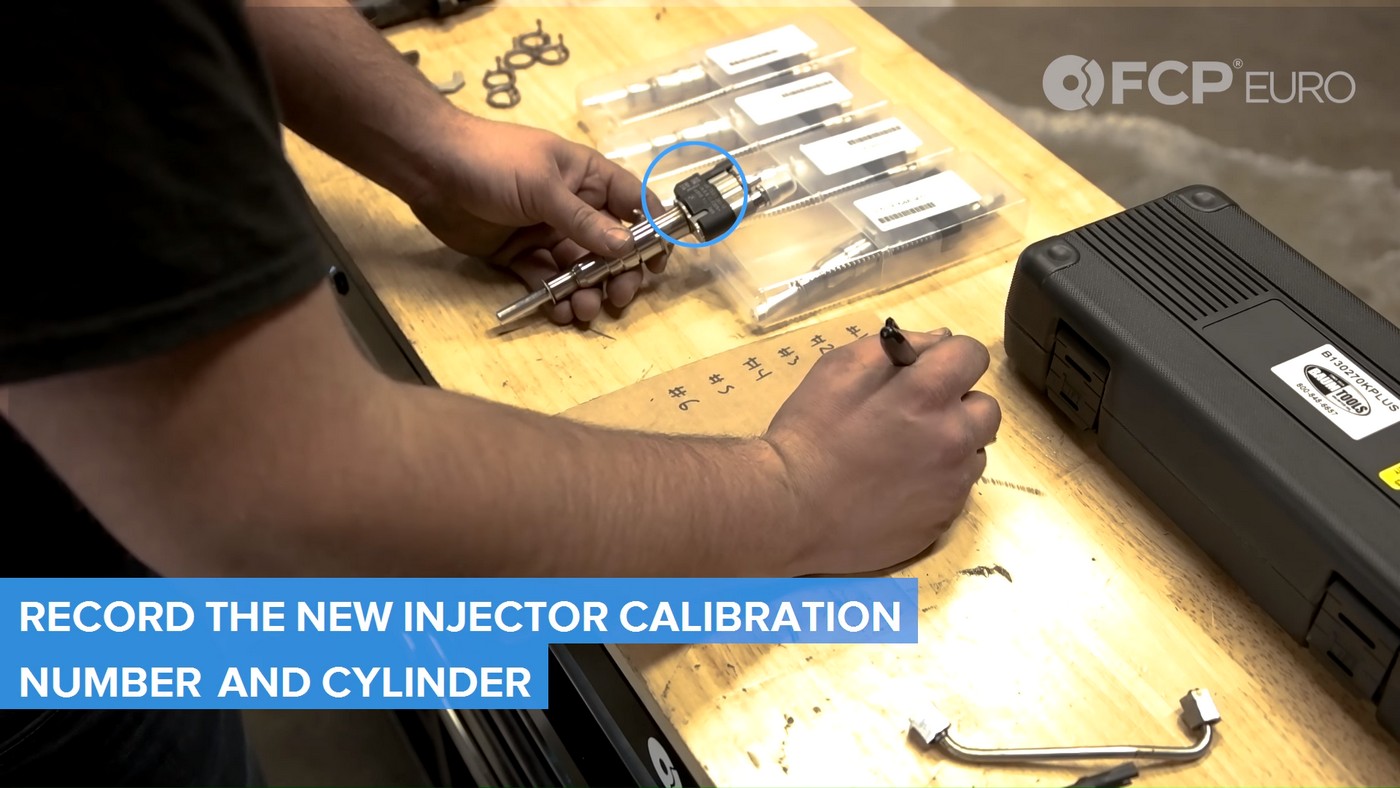

Step 5: Record the Injector Calibration Numbers and Install New Injectors

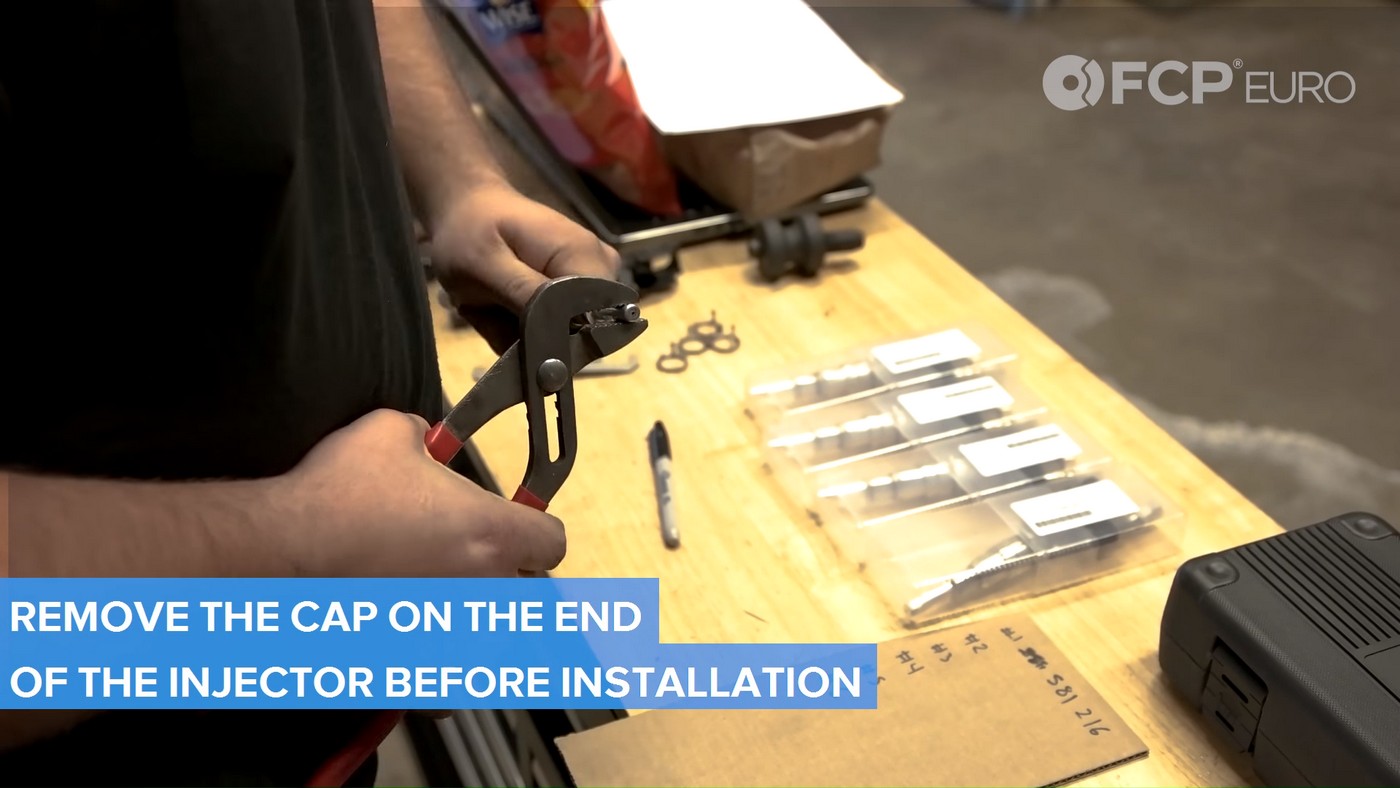

Before installing the new injector, record the calibration numbers; you will need them later to perform a DME calibration for the new injectors. The top number on the injector is the energy calibration number and the lower number is the flow calibration number. After you record the number for the cylinder that the injector is being installed into, install a new decoupling element and remove the protective cap on the tip of the injector. The cap can be difficult to remove as it keeps the Viton seal compressed and the tip clean. Simply twist back and forth as you pull it off.

You're now ready to install the injector by placing it back in the cylinder head. Don't worry about forcing it to bottom out; when you reinstall the retaining clip the injector will bottom out on its own. Reinstall the fuel feed line onto the injector, tighten the flare nut on the injector and the flare nut on the fuel feed line.

Step 6: Reassembly and DME Calibration

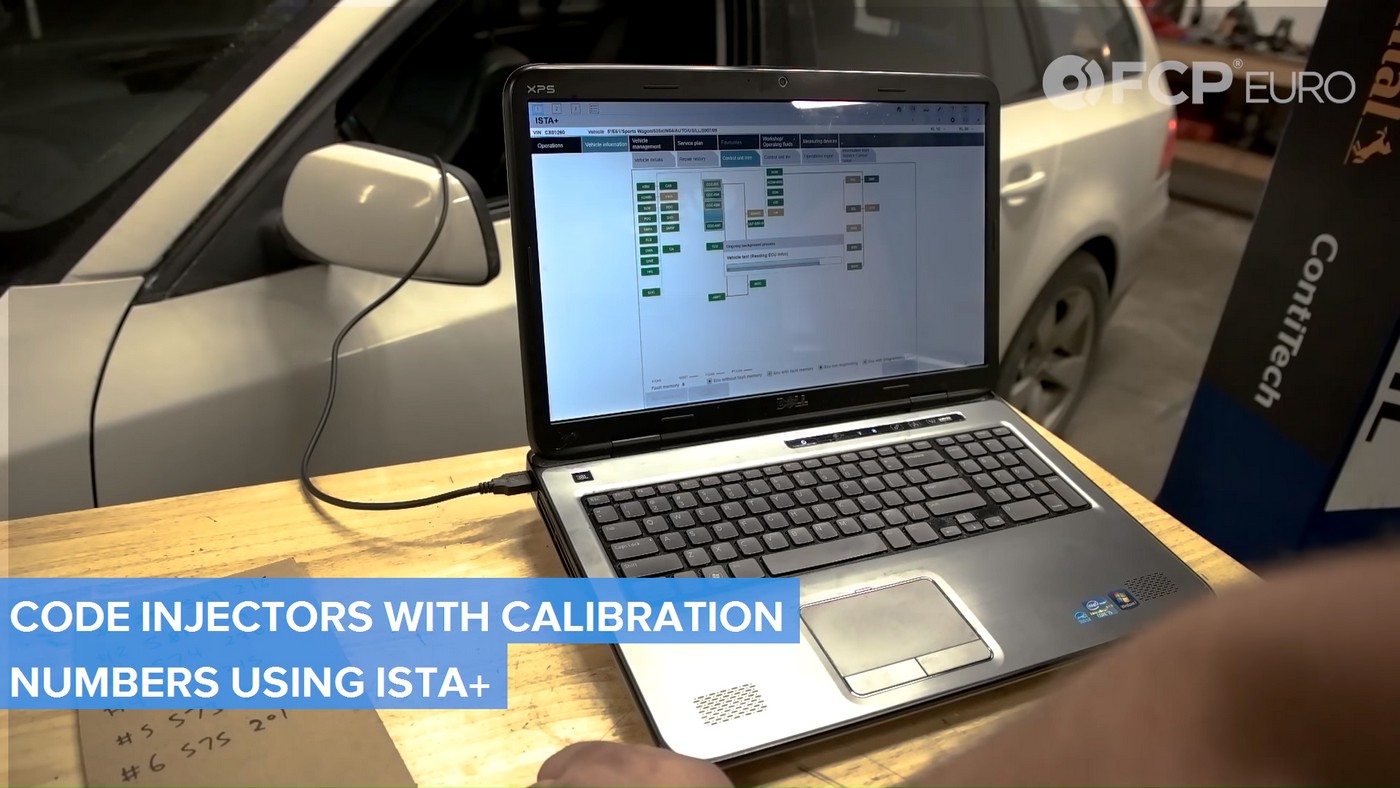

After installing the injectors, reinstall the ignition coils, retaining bracket, and all the electrical connectors. Now you're ready to start the engine. It may take a moment for the engine to start after a long crank; the fuel system needs to build pressure. Once started, make sure to check for any fuel leaks. If there aren't any fuel leaks, you're ready to perform a DME calibration for the new fuel injectors. You can use INPA, ISTA, or another scan tool capable of DME calibration. Enter the required information into the tool, enter the calibration numbers in the required format, and complete the calibration. Now you're all set and can begin putting everything else under the hood back together. If you do not have the ability to perform the calibration, you can safely drive your car to a shop or dealer to have the calibration carried out for you. Technically, it's not harmful to the engine - but we can say for sure that the engine will not perform optimally until the calibration is complete.

Although it may seem intimidating, this is not a difficult job. Having our N54 Injector Kit and the proper tools will make this job go quickly and smoothly. Be sure to check out the video below to see the entire process.