- 09/01/2021

- 6 Min Read

- By: Kyle Bascombe

The Definitive Guide To The Mercedes-Benz AIRMATIC Suspension System

Throughout the last twenty years, Mercedes-Benz equipped numerous vehicles in their lineup with air-ride from the factory. This system, although complex, shouldn't be feared; it's broken up into relatively easy-to-service components.

Introduced on the W220 S-Class for the 2000 model year, Mercedes-Benz began equipping various models throughout their lineup with an air-suspension system dubbed "Mercedes-Benz Airmatic". This system replaced the traditional coil-springs found on cars leading up to this time with air-springs with electronic level control and adaptive damping at all four corners. The combination of adaptive damping that adjusts based on road quality and driving style in concert with air springs makes for an extremely comfortable ride.

Mercedes-Benz Models Equipped with Airmatic Suspension

Mercedes-Benz E-Class (W211)

- E500: 2003-2006

- E550: 2007-2009

- E55: 2003-2006

- E63: 2007-2009

Mercedes-Benz CLS-Class (W219)

- CLS500: 2006

- CLS55: 2006

- CLS550: 2007-2011

- CLS63: 2007-2011

Mercedes-Benz Airmatic Benefits & Features

You might be asking why you would want such a complex system in place of the much simpler coil-spring setup. There are a number of reasons, some of which make it well worth it over the traditional coil-spring suspension.

- Auto-Leveling - Auto leveling compensates for additional passengers or cargo in your car. Not only does this make your car look better cruising down the highway, it keeps the handling dynamics exactly how the engineers designed the car no matter how much weight or where it's added.

- Auto Height Adjustment - When reaching highway speeds, the car will automatically lower itself to improve aerodynamic efficiency. Not only does this result in a more stable car at highway speeds, but this also improves the fuel economy.

- Axle Lift - Have you ever seen low cars scrape their front end on rough roads, speed bumps, or steep driveway entrances? Mercedes-Benz combats this common issue by allowing you to raise the front axle to clear obstacles.

- Selectable Driving Modes - The driver can select between three distinct driving modes: Comfort, Sport 1, and Sport 2. Comfort and Sport 1 are both great for street driving depending on your style, whereas Sport 2 is more suited for perfectly smooth roads or on a track.

- Adaptive Damping - This is one of the most trick parts of the whole system. Under hard acceleration the system reduces axle-lift and under hard braking, it reduces the amount of nosedive. This makes not only for a more comfortable driving experience but improves the handling characteristics greatly.

- The damping profile/driving modes will auto-adjust from "Comfort" to "Sport 1" when driving over 100MPH as well as based on calculated horizontal acceleration.

Mercedes-Benz Airmatic System Components

Airmatic Control Module

This is the brain of the system. It uses inputs from the ECM, ESP module, transmission module, instrument cluster, steering angle sensor, acceleration sensors, and the level/damping switches in the cabin, among others.

As an example, the module can use braking torque or engine torque values to determine when to switch the damping valves and reduce body roll. These adjustments can be performed in milliseconds, which is especially helpful during emergency maneuvers.

Mercedes-Benz CLS-Class & E-Class

The Airmatic control module is located in the passenger compartment right side footwell. You will need to pull back the carpeting to access it where it is mounted on a plate.

Instrument Cluster

You wouldn't think it, but the instrument cluster plays a vital roll in the Airmatic system. The cluster provides warnings for when the vehicle is too low as well as an indicator that the vehicles is rising and current damping levels. This is your first sign when something is wrong with the system.

Level and Damping Control Switch

There are both manual and automatic means to adjust the vehicle level. You can raise the vehicle 20-25mm (market dependent) using a switch near the shift lever. There is a second switch that changes the drive modes of the vehicle. These are the three modes discussed above: Comfort, Sport 1, and Sport 2. Sport 1 and Sport 2 lower the vehicle 15mm (market dependant). The suspension is also adaptive and automatically switches the damping profile to Sport 1 above 100 mph.

Compressor and Compressor Relay/Fuse

The compressor provides the system pressure for raising the vehicle as well as a pressure relief valve for lowering it. The compressor relay is responsible for starting and stopping the compressor.

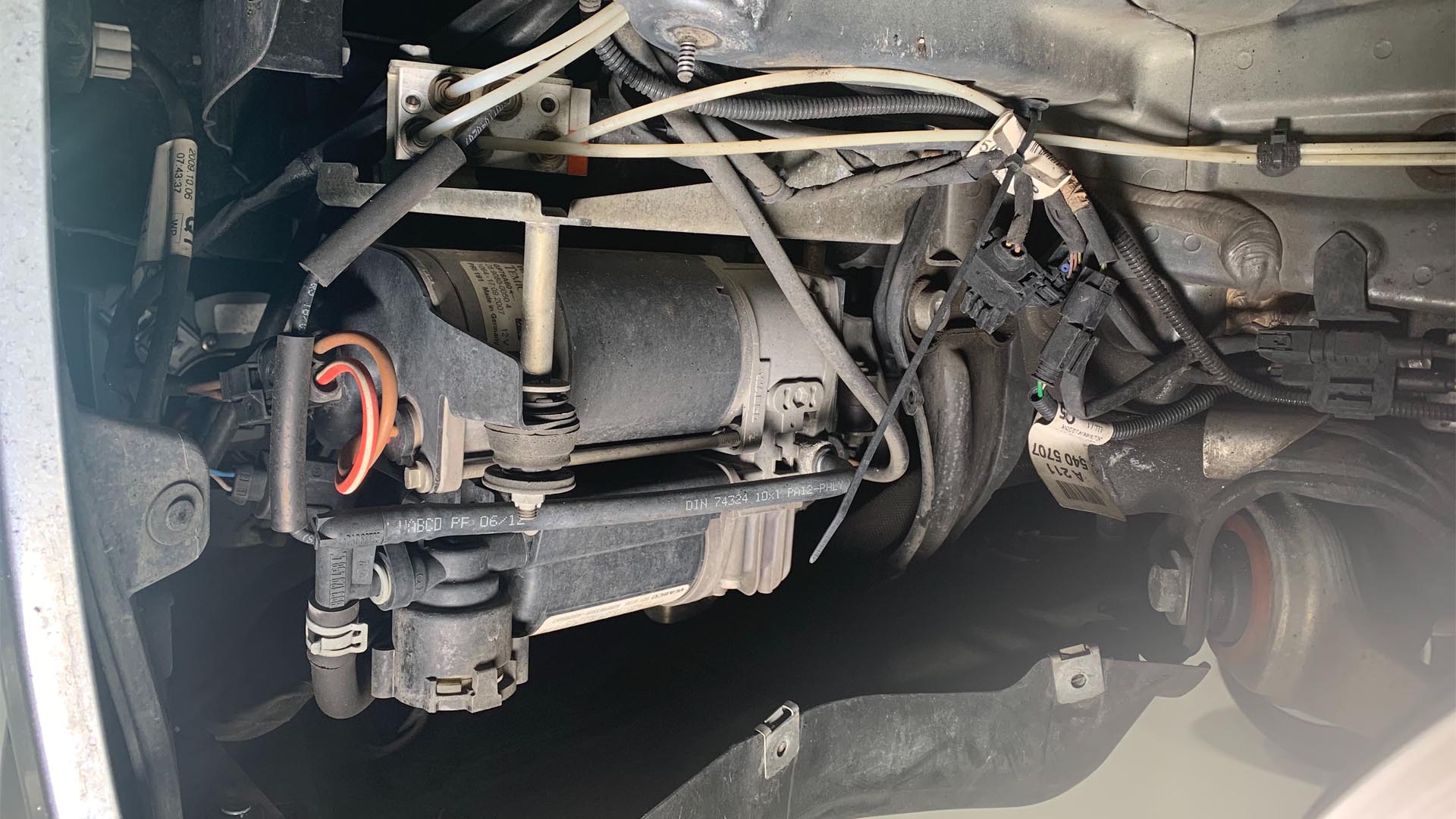

Mercedes-Benz CLS-Class & E-Class Compressor, Relay/Fuse Location

The compressor is located in the forward portion of the front-left wheel well. The compressor relay is located in the left side engine compartment relay/fuse box and is easily identifiable as it is clipped on the rearmost part of the box and is usually black in color. The Airmatic fuse is located in the passenger compartment right side footwell. You will need to pull back the carpeting and the plate that mounts the suspension control module to access the fuse. The fuse is in position 74.

Level Sensors

The levels sensors are mounted on a bracket near the upper control arms on the front of the vehicle. Each sensor is connected to a link rod attached directly to the upper control arm. The sensors produce a voltage that the Airmatic Control Module translates to axle height. There is a single rear axle level sensor located near the rear-left drive axle.

Acceleration Sensors

Located at various points in the interior and exterior of the vehicle. The sensors measure turn rate and lateral acceleration. Information from these sensors are used to calculate vertical and horizontal acceleration.

Mercedes-Benz CLS-Class & E-Class Acceleration Sensor Location

The front lateral sensors are located on the strut tower just forward of the front air strut.

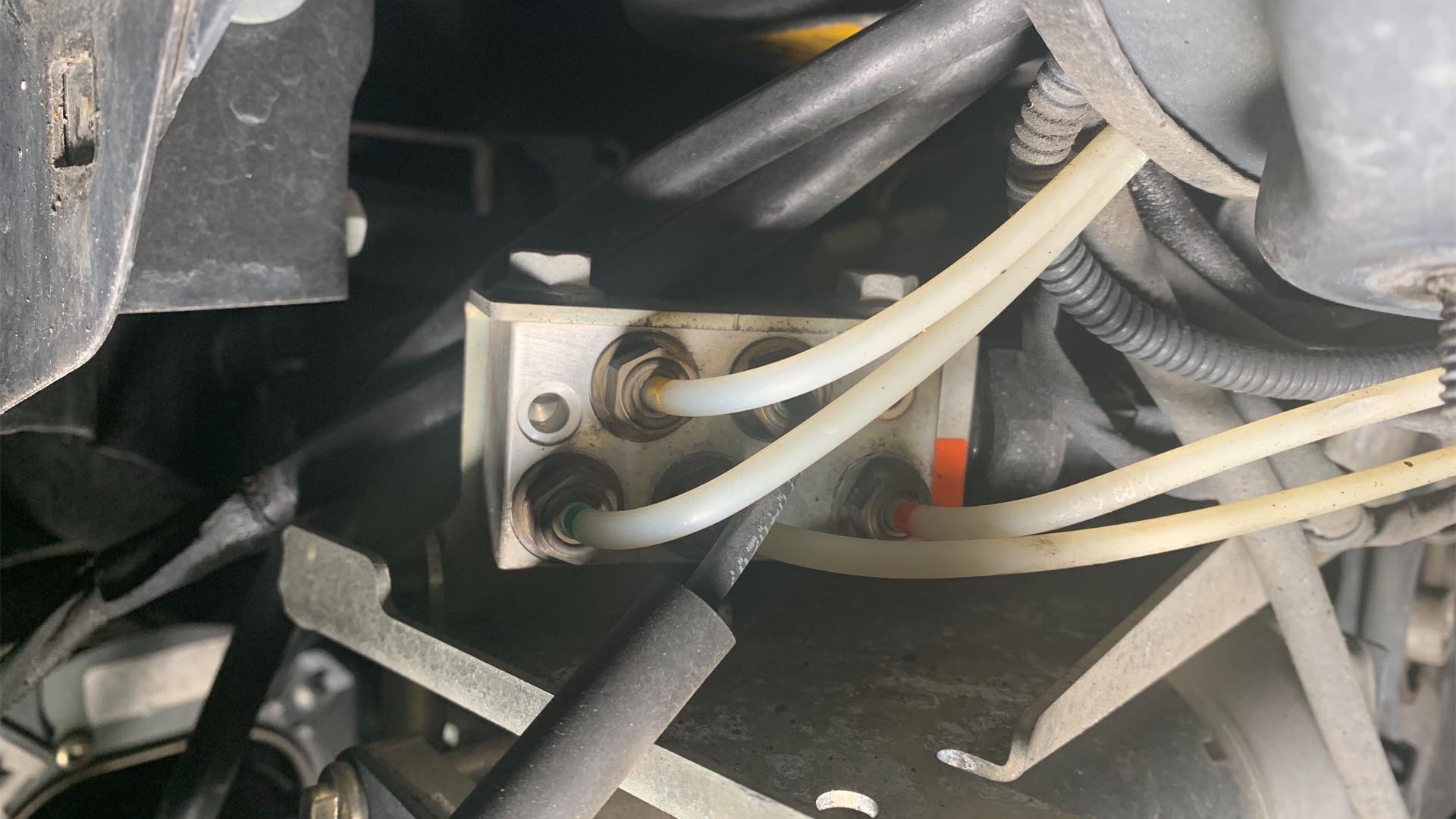

Valve Block Assembly

This assembly distributes air to each of the front struts and to the rear axle. It also has a direct connection to the air compressor and has the pressure sensor for the system.

Mercedes-Benz CLS-Class & E-Class Valve Block Location

The valve is easy to locate as it's positioned directly next to the compressor.

Main Reservoir

The main reservoir is a metal pressure vessel that stores compressed air at 13-16bar and is used to level the vehicle. This tank is incorporated to reduce the dependency on the air compressor and to reduce noise. The tank is most commonly used to level the vehicle when the door or trunk is first opened.

Mercedes-Benz CLS-Class & E-Class Main Reservoir Location

The main reservoir is easy to locate and access. It's located in the right rear corner of the trunk.

Strut & Damper Assembly

The air strut is an assembly consisting of a monotube shock absorber with electromagnetic damping valves that change setting based on commands from the suspension control module. An air spring assembly sits on top of the strut and is responsible for height adjustment as well as air spring damping. The air spring contains two chambers, one air chamber is used when a firm spring rate is needed and both chambers are filled for a softer spring rate.

Air Springs

Located in the rear of the vehicle, the air springs consist of an electronically-controlled main cell and an additional reservoir. The springs mount to the subframe and lower control arm. If you need to replace them, it requires the subframe to be dropped if factory style air springs are going to be used. Out of all the components in the system, this is one is the most prone to leaks. If moisture gets in the air spring reservoir, the aluminum corrodes and becomes pitted where it is clamped to the rubber hose, forming an incomplete seal.

Rear Axle Distribution Block

The way the air system is designed, there isn't a direct air line connection between the valve block assembly and the individual rear air springs. The distribution block sends pressure from a single connection at the valve block to individual lines that go to each air spring.

Mercedes-Benz Airmatic System Maintenance/Common Failures

As this system was introduced nearly twenty-years ago now, maintenance is becoming a must and you'll probably want to keep an eye out for the common failures of the system.

- Air Strut Assembly - ~105,000 Miles

- The dampers usually still have a little life left in them, however, the air bladders begin to fail around this mileage. You want to listen closely for a hissing noise after the suspension begins to raise.

- Air Spring - ~115,000 Miles

- This is the most common failure on Mercedes-Benz equipped with Airmatic. It's common for them to leak from the hose connection at the reservoir as well as have a bag rupture from age. Solenoids are part of the rear bags, so if one side is lower than the other, suspect a faulty bag.

- Dampers - ~ 115,000 Miles

- These are simple and as they age there will be a noticeable degradation of the ride quality. You might also notice side-to-side body motion that's not controlled as well as pitching and diving.

- Valve Block - No Mileage

- The valve blocks in W211/219 are not as failure prone as other Mercedes chassis where the solenoids are integrated such as W220/164. If you remove an airline from the valve block and observe aluminum pitting or oxidation, we would recommend replacement.

- Ride Height Sensors - No Mileage

- Failures of the ride height sensors are sporadic. Sensor brackets get bent or damaged, leading to incorrect or implausible signals. Front links have been known to dry up and pop off.

- Compressor - ~125,000 Miles

- On a higher mileage vehicle consider replacing the compressor along with relay and filter on vehicles that have had multiple bag failures or vehicles that had leaking components that were on the vehicle for an extended period of time. These situations tend to overwork the compressor and shorten its life.

Mercedes-Benz Airmatic Suspension Troubleshooting Tips

- Rear Suspension Airbags

- The rear suspension airbags are the most common failure component on this chassis. When one side of the rear is lower than the other, this typically is an airbag failure. To determine if one side is lower, raise the vehicle to the highest setting and the lower it. From there, measure the ride height at each corner of the vehicle and record. Let the vehicle sit overnight with the air suspension computer unplugged and measure the ride height after that. If both the initial measurement and the measurement after the vehicle has sat for one day is lower on one side, you can assume that a faulty airbag is the culprit. Unplugging the suspension module will prevent the vehicle from automatically re-leveling overnight.

When you replace the air spring with a Genuine or OE component, you can replace just a single unit. If you are replacing it with an aftermarket unit, both sides should be replaced simultaneously. This is exceedingly important if you don't have the factory-style scan tool to carry out a level caliration after air spring replacement. This is done to account for the differences in air volume that occur with aftermarket products that omit the additional reservoir.

- The rear suspension airbags are the most common failure component on this chassis. When one side of the rear is lower than the other, this typically is an airbag failure. To determine if one side is lower, raise the vehicle to the highest setting and the lower it. From there, measure the ride height at each corner of the vehicle and record. Let the vehicle sit overnight with the air suspension computer unplugged and measure the ride height after that. If both the initial measurement and the measurement after the vehicle has sat for one day is lower on one side, you can assume that a faulty airbag is the culprit. Unplugging the suspension module will prevent the vehicle from automatically re-leveling overnight.

- Weak Airmatic Compressor

- A weak compressor will prevent the vehicle from rising or may cause it to rise slowly. If you have the appropriate scan tool, fault codes for "critical vehicle level" or "recovery time during filling" will be present. A healthy compressor should output a minimum of 10 bar on the scan tool. Output can also be verified using a gauge at the compressor output.

A compressor that doesn't run at all could be the result of a bad compressor or lack of voltage to the compressor. It's not uncommon for relays to stick and burn out a compressor. If you see battery voltage at the suspension compressor and it still doesn't run, replace the compressor and the compressor relay. If battery voltage isn't present, replace the relay and fuse and re-test.

- Arnott branded compressors sold through us include the compressor relay which should always be replaced.

- A weak compressor will prevent the vehicle from rising or may cause it to rise slowly. If you have the appropriate scan tool, fault codes for "critical vehicle level" or "recovery time during filling" will be present. A healthy compressor should output a minimum of 10 bar on the scan tool. Output can also be verified using a gauge at the compressor output.

- Failed Front Strut Assembly

- Failed front air struts normally fill and almost immediately start dropping when they're not operating properly. An audible hissing at the strut assembly is a good indicator of a front strut failure. If the air strut doesn't rise with the compressor activated, manually fill the strut with pressurized air to confirm that you don't have a compressor issue. These can simply be a weak compressor or an air leak between the compressor and the valve block or the valve block and the strut.

- You can manually fill the strut without a factory style scan tool. To do so, you'll want to consult this short article on how to do so with a specific plug and a 9-volt battery.

- Failed front air struts normally fill and almost immediately start dropping when they're not operating properly. An audible hissing at the strut assembly is a good indicator of a front strut failure. If the air strut doesn't rise with the compressor activated, manually fill the strut with pressurized air to confirm that you don't have a compressor issue. These can simply be a weak compressor or an air leak between the compressor and the valve block or the valve block and the strut.

- Level Sensor Failure

- If your vehicle is noticeably low but there isn't a red error message on the instrument cluster reading "vehicle level too low", a level sensor (or its linkage) is at fault. This is a common issue after hitting a large object or a large pothole, or if the rear linkage becomes bent.

- Height Loss Overnight in Cold Climates

- A certain amount of suspension drop is normal in extremely cold climates. This is due to thermal contraction and can drop up to 30mm in one day. This is perfectly normal and is within the engineered parameters.

Specialty Tools Required For Servicing Mercedes-Benz Airmatic Suspension

The Airmatic system on your Mercedes-Benz is user-friendly when it comes to servicing it. While none of the tools listed below are strictly required, they are extremely helpful to have when diagnosing or servicing the system.

- Baum Mercedes-Benz Airmatic Suspension Line Socket

- Clearance at the rear airbags is limited so having this special socket is useful. In a pinch a 10mm wrench can work, but this is also useful for reaching the connectors to the valve block as well.

- CTA Mercedes-Benz Air Suspension Tester

- This is useful if you do not have a scan tool and need to verify sufficient pneumatic output to lift the vehicle. This gauge contains an M8 fitting that can be threaded directly into the compressor outlet port.

- Autel MD808 OBD Scanner

- This scan tool isn't necessary to perform maintenance, but it's extremely handy to have. This will accurately display the pneumatic output from the computer.

If you found this guide helpful, have any questions or comments, or would like to see anything added, leave a comment in the field below. This guide will be constantly updated as more information and opportunities to document additional content becomes available. If you would like to view more Mercedes-Benz content, you can visit our Mercedes hub at mercedes.fcpeuro.com.